Benefits of Using 3D Puff Vinyl

Here are the benefits of using 3D Puff Vinyl in detail:

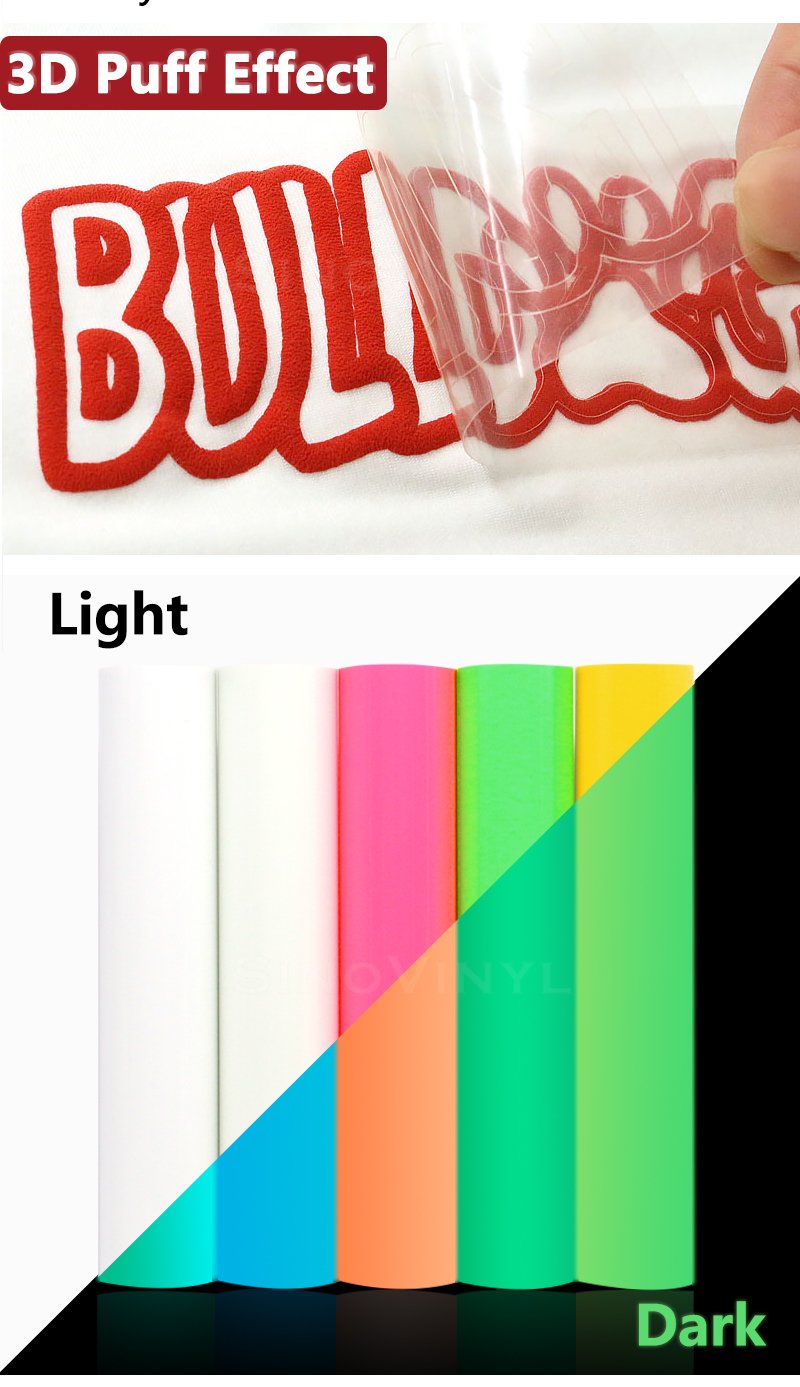

1. Enhanced Texture and Dimensionality:

– 3D puff vinyl adds a tactile dimension to your designs.

2. Durability and Washability:

– 3D puff vinyl is known for its durability. Once properly applied and cured, it can withstand regular wear and tear without losing its texture or vibrancy.

– It maintains its form and texture even after numerous washes, ensuring that your designs stay intact and looking great for a long time.

3. Suitable Fabrics and Applications:

– 3D puff vinyl works well on a variety of fabrics, including cotton, polyester, blends, and more.

4. Elevated Aesthetics:

– The raised texture of 3D puff vinyl adds depth and dimension to your designs, giving them a high-end, premium look.

5. Attention-Grabbing Designs:

– The dimensional quality of 3D puff vinyl naturally draws attention.

6. Versatility in Layering and Combinations:

– 3D puff vinyl can be layered with other types of vinyl or incorporated into mixed-media designs, allowing for even more creative possibilities.

– By combining 3D puff vinyl with other materials, you can achieve unique and complex effects that would be challenging to create with a single type of vinyl.

7. Customization and Personalization:

– With 3D puff vinyl, you have the ability to create one-of-a-kind, customized designs.

Tools and Materials for Applying 3D Puff Vinyl

Here are the tools and materials you’ll need for applying 3D Puff Vinyl:

1. Heat Press Machine

– A high-quality heat press is essential for achieving the best results with 3D puff vinyl. Look for one with the following specifications:

– Temperature range: 300-330°F (149-166°C)

– Pressure adjustment: Ensure it can exert enough pressure for the puff effect.

– Timer: Helps in controlling the application time accurately.

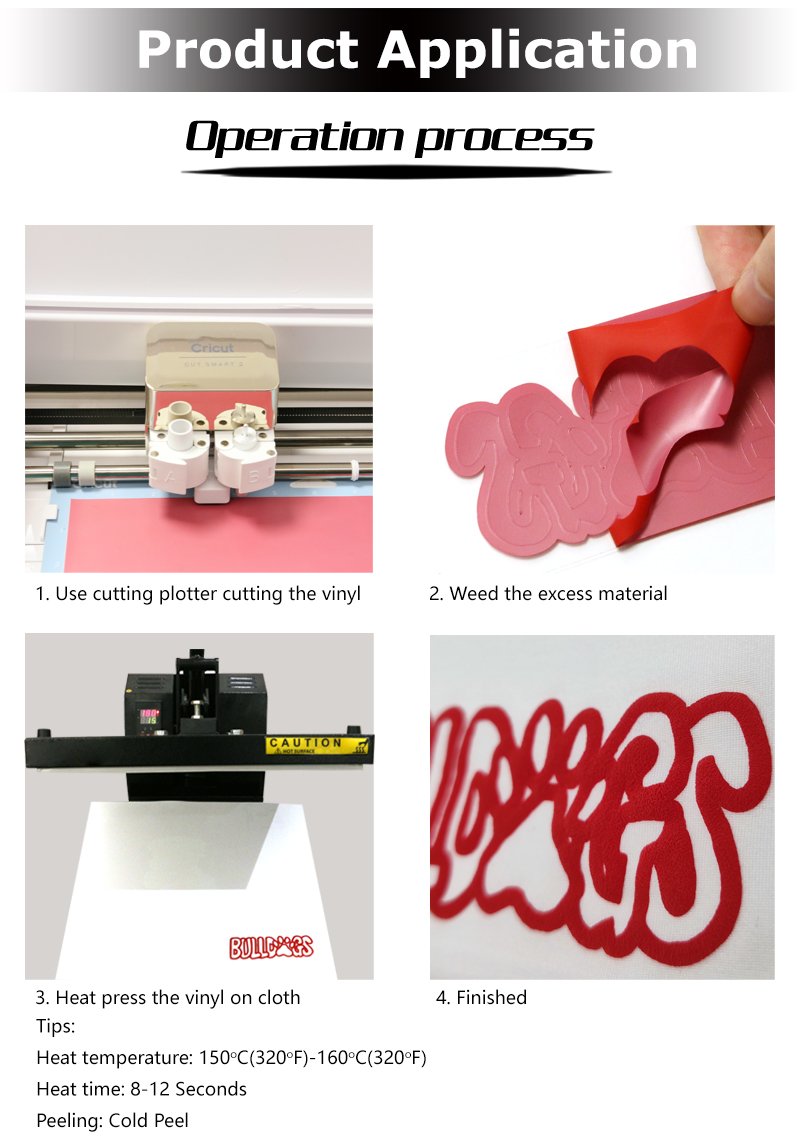

2. Cutting Machine

– A vinyl cutting machine (like a Silhouette or Cricut) with a fine-point blade for precise cutting of the 3D puff vinyl.

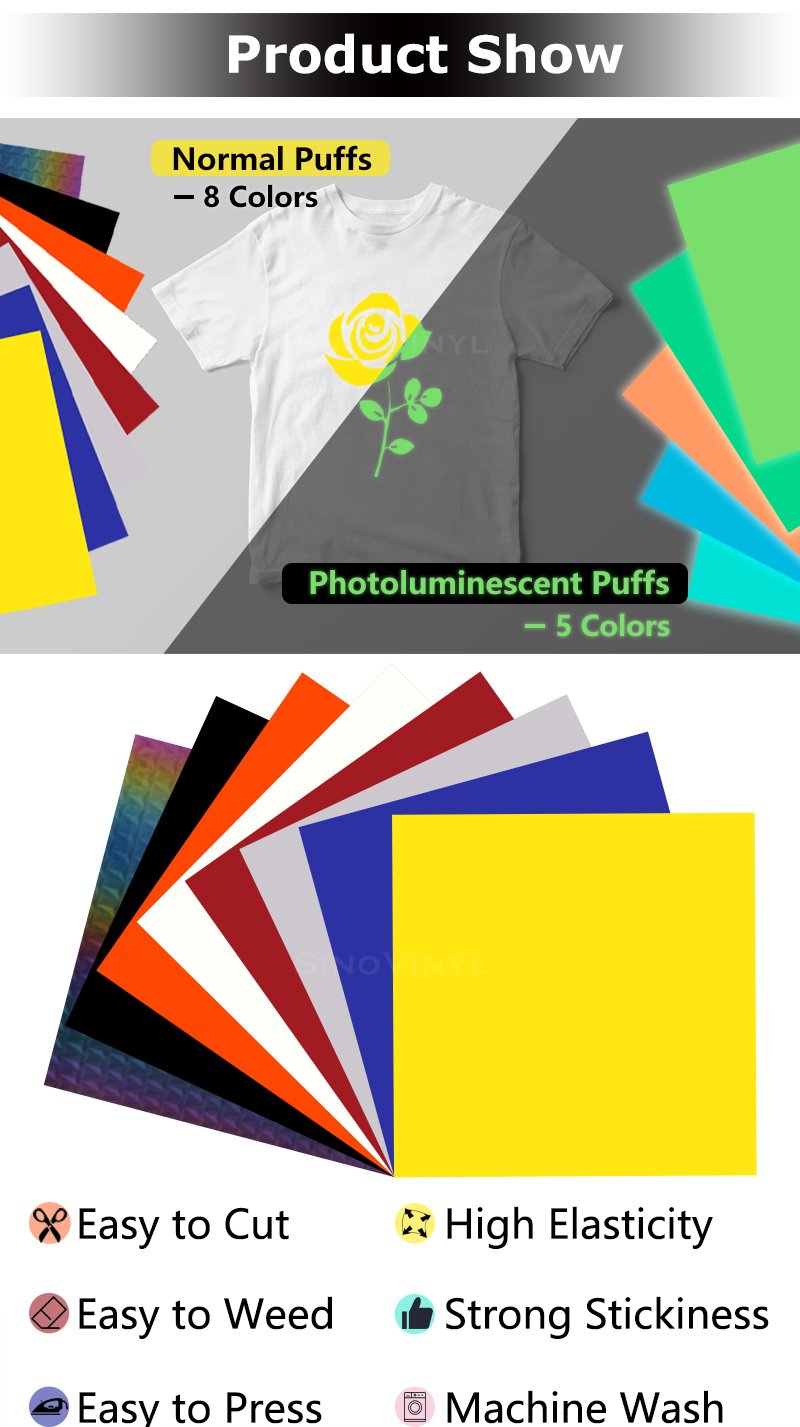

3. 3D Puff Heat Transfer Vinyl

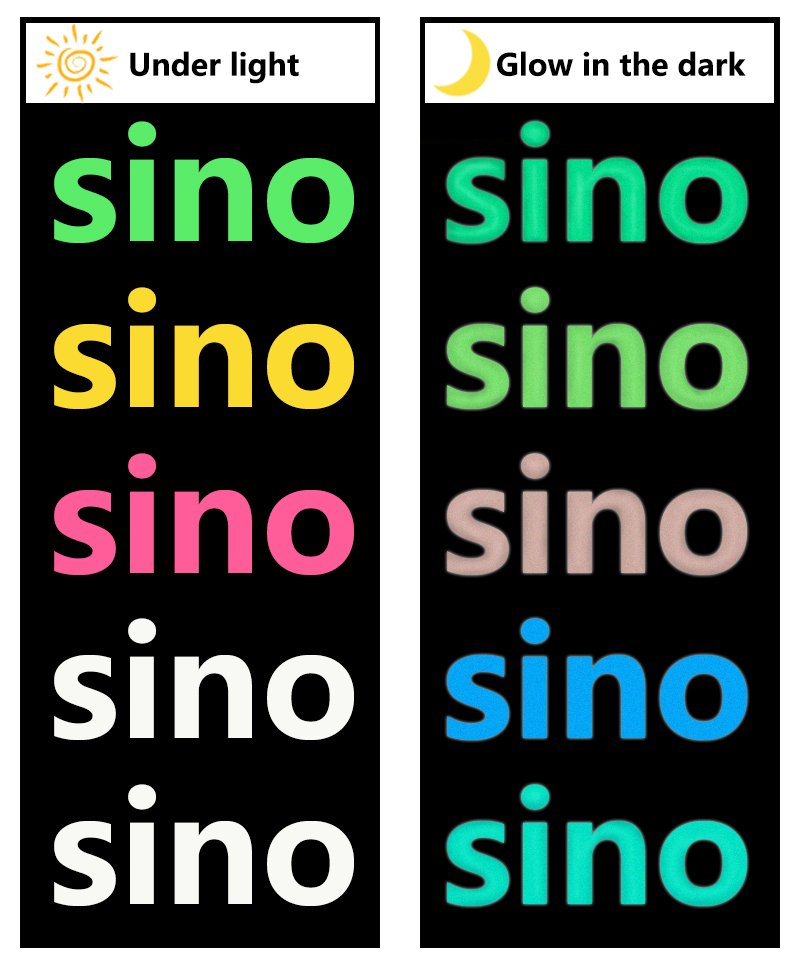

– Choose a high-quality 3D puff vinyl in the colors and finishes you desire. It typically comes in sheets or rolls.

4. Weeding Tools

– Precision weeding tools to remove excess vinyl from the design.

5. Teflon or Silicone Sheets

– These are used to protect both the vinyl and the garment during the heat application process.

6. Parchment Paper or Release Paper

– Helps in preventing the vinyl from sticking to the heat press.

7. Garments

– Use fabrics that are compatible with 3D puff vinyl. Ideal fabrics include:

– Cotton: Natural fibers work best for adhesion and puffing.

– Cotton-polyester blends: These are generally suitable, but test a small area first.

– Avoid fabrics with high levels of synthetic fibers.

8. Lint Roller or Brush

– To remove any lint or debris from the garment surface before applying the vinyl.

9. Heat Resistant Tape

– Optional but useful for securing the vinyl in place during the heat press process.

10. Pillow or Pad

– Especially important for garments with seams or uneven surfaces. It helps ensure even pressure during heat application.

11. Thermal Heat Gloves

– Protect your hands from the heat when handling garments after pressing.

12. Protective Eyewear

– Safety first! Protect your eyes when working with heat press equipment.

13. Work Area

– A clean, flat, and clutter-free surface for cutting, weeding, and pressing.

By having these tools and materials on hand, you’ll be well-equipped to work with 3D puff heat transfer vinyl and achieve professional-looking results.