What is Puff Heat Transfer Vinyl: A Comprehensive Introduction

Introduction to Puff Heat Transfer Vinyl

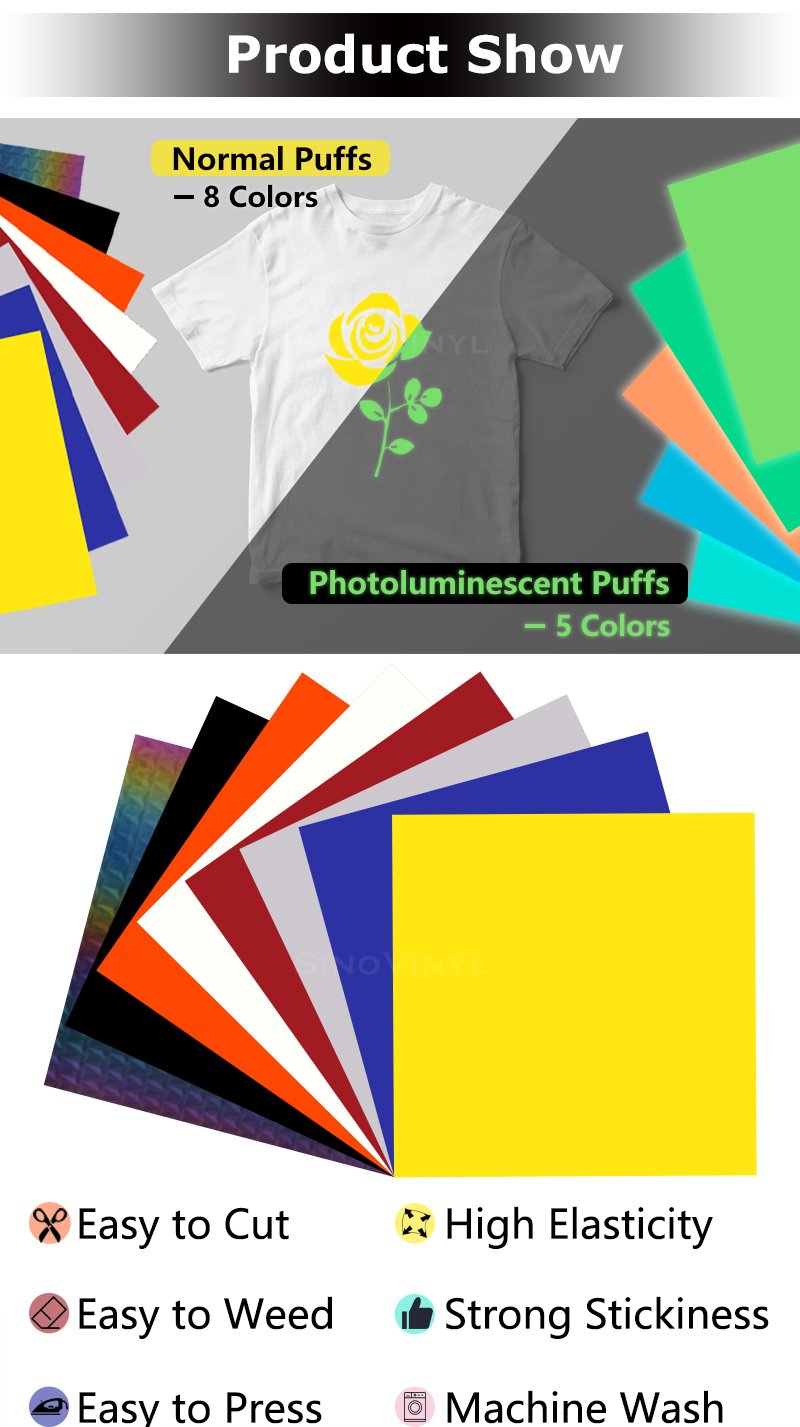

Puff Heat Transfer Vinyl, also known as 3D Heat Transfer Vinyl or Raised Heat Transfer Vinyl, is a popular and innovative material used in the world of garment decoration and custom apparel. It offers a unique way to add dimension, texture, and depth to designs, creating eye-catching and stand-out graphics on various fabrics.

What sets Heat Transfer Vinyl apart from regular vinyl is its ability to expand and puff up when exposed to heat during the application process. This special characteristic allows the vinyl to lift off the fabric, giving the design a raised and three-dimensional appearance. The result is a visually appealing effect that enhances the overall look and feel of the apparel, making it a favorite among designers, crafters, and custom garment businesses.

How Puff Heat Transfer Vinyl Works

Puff Heat Transfer Vinyl is composed of a combination of materials, including a heat-activated adhesive layer and a special foam or puff layer. The adhesive layer is responsible for bonding the vinyl to the fabric, while the foam layer expands when heated, creating the puffed effect. The expansion of the foam raises the vinyl above the fabric’s surface, giving the design its 3D appearance.

Application Process

The application process for Heat Transfer Vinyl is similar to that of regular heat transfer vinyl, but with an additional step to achieve the puff effect. Here’s a general overview of the application process:

1. Design Creation

Create your desired design using graphic design software or choose from pre-made designs available on various platforms.

2. Cutting

Load the Heat Transfer Vinyl onto a cutting machine (such as a vinyl cutter) and cut the design in reverse.

3. Weeding

Remove the excess vinyl from the backing, leaving only the design you want to transfer.

4. Heat Pressing

Pre-heat your fabric to remove any moisture or wrinkles. Place the cut design on the fabric with the carrier sheet facing up. Heat press the design at the recommended temperature and time specified by the vinyl manufacturer.

5. Puffing

After the initial heat pressing, carefully lift the carrier sheet to expose the puff layer. Cover the design with a heat-resistant material (like a Teflon sheet) and press again for a few seconds. The heat activates the foam, causing it to expand and create the puff effect.

Advantages of Puff Heat Transfer Vinyl

– Unique 3D Effect

It adds depth and dimension to designs, making them visually appealing and captivating.

– Standout Designs

With its textured appearance, Heat Transfer Vinyl allows your creations to stand out from the crowd, making it ideal for custom apparel and branded merchandise.

– Versatility

It works well on a wide range of fabrics, including cotton, polyester, blends, and more.

– Durability

When properly applied and cared for, the Vinyl designs can withstand repeated washings and maintain their 3D effect.

– Ease of Use

It can be applied with a standard heat press, making it accessible to both beginners and experienced crafters.

In conclusion, it offers a fascinating and creative way to elevate your designs and transform ordinary garments into extraordinary pieces of art. Its ability to add depth and texture has made it a favorite among designers and crafters, opening up new possibilities for custom apparel decoration. Whether you’re a hobbyist or a professional, experimenting with the Heat Transfer Vinyl can bring your designs to life and leave a lasting impression on your audience.

Troubleshooting Common Issues with Puff Heat Transfer Vinyl Application

When working with puff heat transfer vinyl, you may encounter some common issues during the application process. Here are some troubleshooting tips for these issues:

1. Uneven Puffing

If your heat transfer vinyl expands unevenly or creates inconsistent puffing across the design, the most probable cause is improper temperature or pressure settings. Make sure to follow the manufacturer’s recommended settings and test on a small area before applying to the entire design.

2. Incomplete Puffing

If the heat transfer vinyl fails to expand fully during the application process, the temperature may be too low, or the pressing time might be insufficient. Check your heat press settings and try increasing the time or temperature slightly.

3. Wrinkles or Bubbles

Wrinkles and bubbles can occur if the heat transfer vinyl is not adhered properly to the fabric. To avoid this issue, ensure that you apply even pressure during the heat transfer process and that there are no wrinkles or folds in the fabric before pressing.

4. Peeling or Adhesion Issues

If the puff heat transfer vinyl starts to peel off the fabric after application, it could be due to inadequate pressing or low-quality vinyl. Double-check your heat press settings and use high-quality heat transfer vinyl to ensure a secure bond.

5. Burnt or Discolored Vinyl

Excessive heat or pressing time can lead to burnt or discolored heat transfer vinyl. Always follow the recommended settings and avoid overexposing the vinyl to heat.

6. Residue on Heat Press

Sometimes, the puff heat transfer vinyl may leave residue on your heat press, causing it to transfer onto future projects. Regularly clean your heat press to prevent this issue and maintain the quality of your transfers.

7. Lack of Adhesive

If the puff heat transfer vinyl does not adhere to the fabric at all, the vinyl may have lost its adhesive properties due to exposure to high temperatures or improper storage. Ensure that you store the vinyl in a cool, dry place and avoid exposing it to direct sunlight or extreme temperatures.

8. Peeling During Cold Peel

Some puff heat transfer vinyl requires a cold peel method, which means peeling off the carrier sheet after cooling down. If the vinyl doesn’t peel easily, try waiting for a few more seconds to allow it to cool further before attempting to peel.

9. Ink Bleeding

When applying puff heat transfer vinyl to colored or sublimated garments, ink bleeding can occur. To prevent this issue, use a heat transfer cover sheet or parchment paper between the vinyl and the garment to protect the vinyl from the dye.

10. Incorrect Cutting Settings

If you are using a cutting machine to cut the puff heat transfer vinyl, make sure the blade depth and cutting force are set correctly to achieve clean and precise cuts.

Remember that practice makes perfect when working with puff heat transfer vinyl. Experimenting with different settings and techniques will help you overcome these common issues and achieve outstanding results in your projects.