Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl

Brand: SINOVINYL®

Model Number: SINO-HTV-PR

Size: 25x30cm 10×12″, 0.5x25M/20″x82FT, the size can be customized

Style: Printable etc.

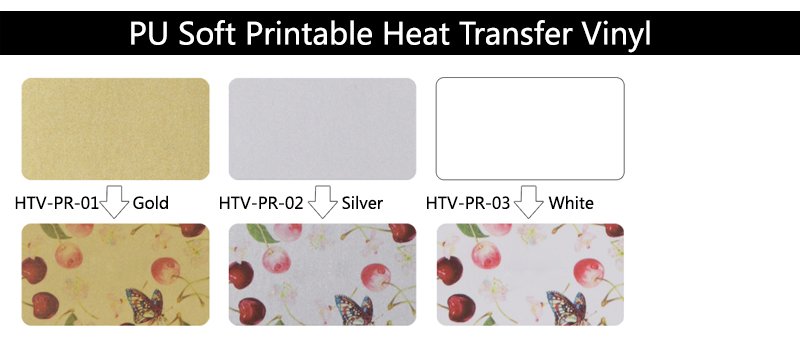

Color: Multiple colors

Transfer Pressure: 20-30 pound

Heat temperature: 150-160°C/302-320°F

Heat time: 8-12 seconds

Peeling method: Cold peel

Application: T-shirt, clothing, textiles, cotton, fabric

Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl

Traditional heat transfer vinyl involves cutting solid-colored vinyl sheets or rolls into desired shapes and designs and then heat pressing them onto fabrics. This is where Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl comes into play.

Unlike traditional vinyl, Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl is specially designed to be compatible with eco solvent inkjet printers. The vinyl itself is crafted with a receptive surface that bonds effectively with these eco solvent inks, allowing them to be printed directly onto the vinyl.

The process of using Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl involves the following steps:

1. Design

Create or choose a design using graphic design software that is compatible with your eco solvent inkjet printer. This could include photographs, complex patterns, intricate artwork, or any design that you want to transfer to fabric.

2. Printing

Load the Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl into your eco solvent inkjet printer. Print the chosen design onto the vinyl using the eco solvent inks. The vinyl’s receptive surface ensures that the inks adhere properly and retain their vibrancy.

3. Cutting

After printing, use a cutting machine to precisely cut around the printed design. This step ensures that only the desired portion of the vinyl is transferred onto the fabric.

4. Weeding

Carefully remove the excess vinyl around the cut design, leaving only the parts that you want to transfer.

5. Heat Transfer

Preheat the fabric where you want to apply the design to remove any moisture or wrinkles. Place the weeded design on the fabric with the printed side facing up. Apply heat and pressure using a heat press machine. The heat and pressure activate the adhesive on the back of the vinyl, allowing it to bond securely with the fabric.

Whether you’re creating personalized apparel, promotional products, sports uniforms, or artistic pieces, Printable Eco Solvent Inkjet Printing PU Heat Transfer Vinyl enables you to achieve a level of customization and intricacy that was previously challenging with traditional heat transfer methods.