When it comes to heat transfer vinyl (HTV) removal, having the right tools and materials can make the process much easier and help prevent damage to your fabrics. Here are some essential tools and materials you’ll need when you are going to remove heat transfer vinyl:

1. Weeding Tool

A weeding tool is a small, pointed tool used to peel off the unwanted vinyl from the carrier sheet. It allows for precise and delicate removal of HTV.

2. Heat Source

You’ll need a heat source, such as an iron or a heat press, to apply heat to the HTV. This will help loosen the adhesive, making it easier to remove the vinyl.

3. Heat Resistant Mat or Pad

To protect your work surface from heat and potential damage, it’s advisable to use a heat-resistant mat or pad under the fabric while removing HTV.

4. Adhesive Remover or Solvent

Sometimes, stubborn adhesive residue may remain on the fabric after HTV removal. An adhesive remover or solvent can help dissolve and remove this residue effectively.

5. Lint Roller or Adhesive Tape

A lint roller or adhesive tape can be used to pick up small vinyl scraps and debris left behind during the removal process.

6. Cotton Swabs or Q-Tips

These are helpful for applying adhesive remover to specific areas with precision.

7. Heat Resistant Gloves

Protect your hands from potential burns when using a heat source like an iron or heat press.

8. Protective Eye Gear

If using a heat gun or any other tool that may release particles or debris, wearing protective eye gear is a good safety measure.

9. Tweezers

Tweezers can be useful for removing small, stubborn vinyl pieces or for delicate weeding tasks.

10. Safety Pin or Sewing Needle

In some cases, a safety pin or sewing needle can be used to lift the edge of the HTV, making it easier to peel off.

11. Heat Transfer Cover Sheet or Parchment Paper

When using heat to remove HTV, a heat transfer cover sheet or parchment paper can protect the vinyl and prevent it from sticking to the iron or heat press.

12. Rubbing Alcohol (Isopropyl Alcohol)

Rubbing alcohol can help clean the fabric surface after HTV removal and remove any remaining adhesive residue.

Make sure to follow safety guidelines and manufacturer instructions for all tools and materials used during the HTV removal process. Proper tools and techniques will ensure a smooth and successful vinyl removal without damaging your fabrics.

How To Remove Heat Transfer Vinyl?

Removing heat transfer vinyl (HTV) can be necessary if you want to correct mistakes, change designs, or refresh your garments. Here’s a step-by-step explanation of how to remove heat transfer vinyl:

Step 1: Heat Up the Vinyl

Heat is essential in loosening the adhesive of the HTV, making it easier to peel off. If you used an iron to apply the vinyl, set it to a low heat setting and let it warm up. If you used a heat press, set it to a low temperature (around 250-300°F or 120-150°C) and preheat it.

Step 2: Gently Peel Off the Vinyl

Using your fingernail or a pair of tweezers, carefully lift a corner of the heat transfer vinyl. Be gentle to avoid damaging the fabric underneath. Once you have a corner lifted, slowly and steadily peel back the vinyl at a 45-degree angle.

Step 3: Use Heat for Stuck Areas

If you encounter areas where the vinyl is sticking stubbornly, place the cloth over the vinyl and apply heat again using the iron or heat press. This additional heat will help loosen the adhesive, making it easier to peel off the remaining parts.

Step 4: Remove Residue (Optional)

After removing the vinyl, you might find some adhesive residue left on the fabric. If the residue is minimal, you can simply wash the fabric, and the remaining adhesive should come off. For more stubborn residue, you can use an adhesive remover or solvent. Apply a small amount to the affected area and let it sit for a few minutes. Then, gently wipe away the residue with a clean cloth.

Step 5: Wash and Dry the Fabric

Once all the vinyl and adhesive residue are removed, wash the fabric following the care instructions. Use a mild detergent and avoid using fabric softeners or bleach. After washing, allow the fabric to air dry or tumble dry on a low heat setting.

Remember, the success of heat transfer vinyl removal largely depends on the type and quality of the vinyl, as well as the fabric it was applied to. Delicate fabrics might require more caution, while some HTV brands might be easier to remove than others. Always test a small, inconspicuous area before attempting to remove the vinyl from the entire design.

Common Mistakes to Avoid When Applying Heat Transfer Vinyl

Here are some common mistakes to avoid when applying heat transfer vinyl (HTV):

1. Incorrect Temperature and Time

Not using the right temperature and time settings can lead to improper adhesion or cause the vinyl to peel off prematurely. Always follow the manufacturer’s recommendations and conduct a test cut before applying HTV to your project.

2. Peeling the Carrier Sheet Too Quickly

If you remove the carrier sheet immediately after pressing, the vinyl may not have enough time to bond properly with the fabric. Allow the vinyl to cool down for a few seconds before peeling off the carrier sheet.

3. Using the Wrong Fabric

Some fabrics, like nylon or spandex, may not be suitable for HTV application because they can’t withstand the required heat or have a low adhesion surface. Stick to fabrics like cotton, polyester, and blends that are compatible with HTV.

4. Improper Surface Preparation

Failing to clean and pre-press the fabric can prevent the vinyl from adhering correctly. Always ensure that the fabric is clean, dry, and free from any wrinkles or residues before applying HTV.

5. Layering Vinyl Incorrectly

Layering multiple vinyl colors can create stunning designs, but if not done correctly, it can result in uneven application or peeling. Follow layering guidelines and always press the bottom layers before adding additional vinyl.

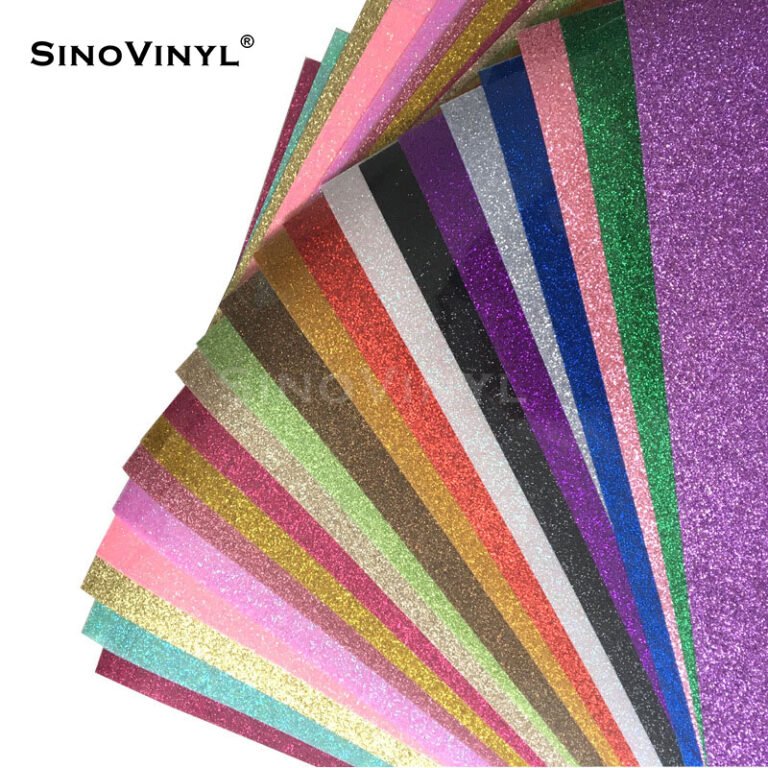

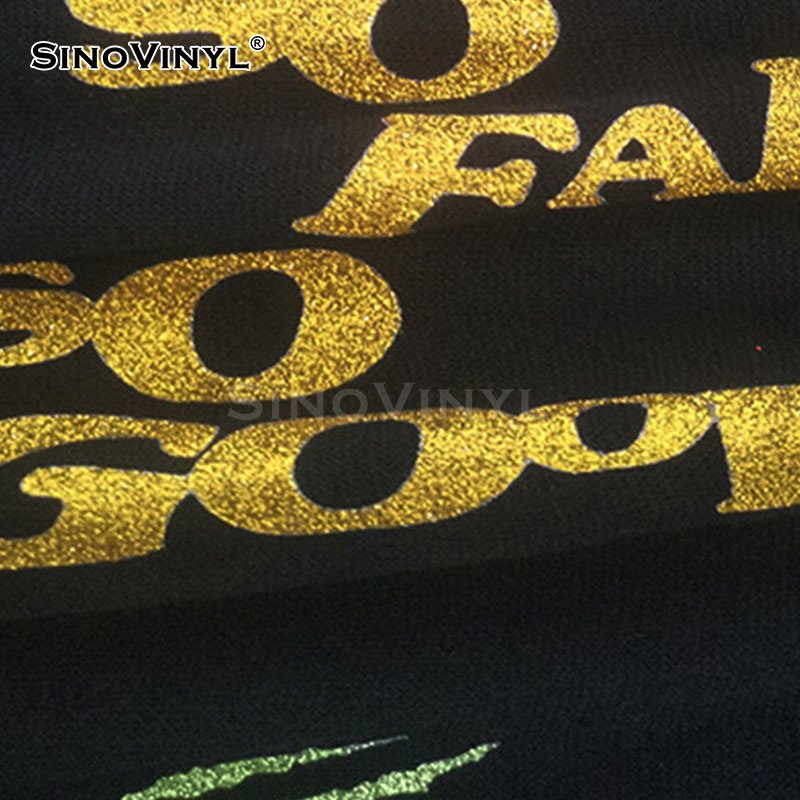

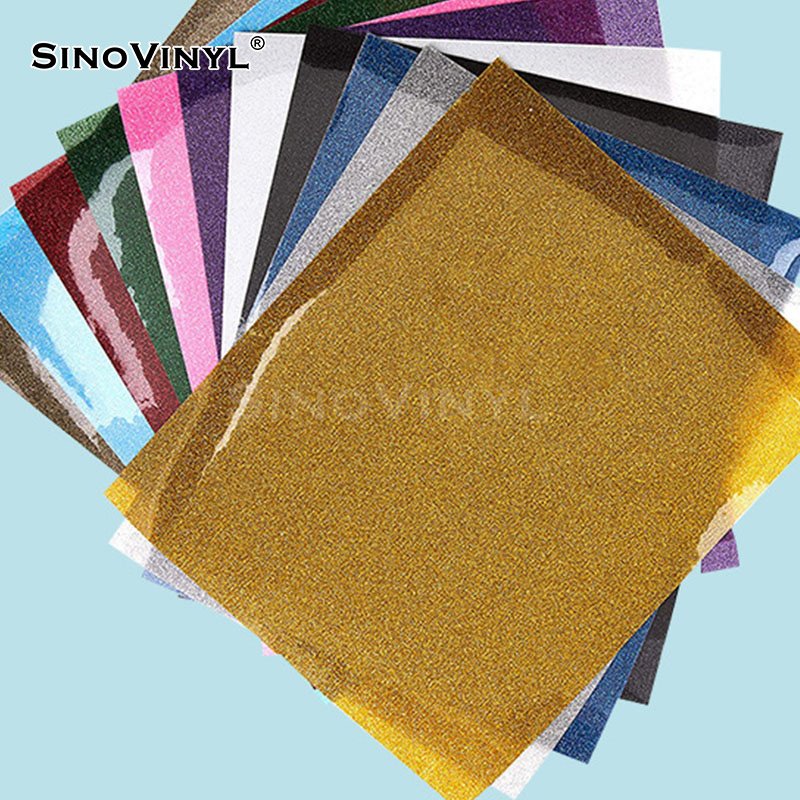

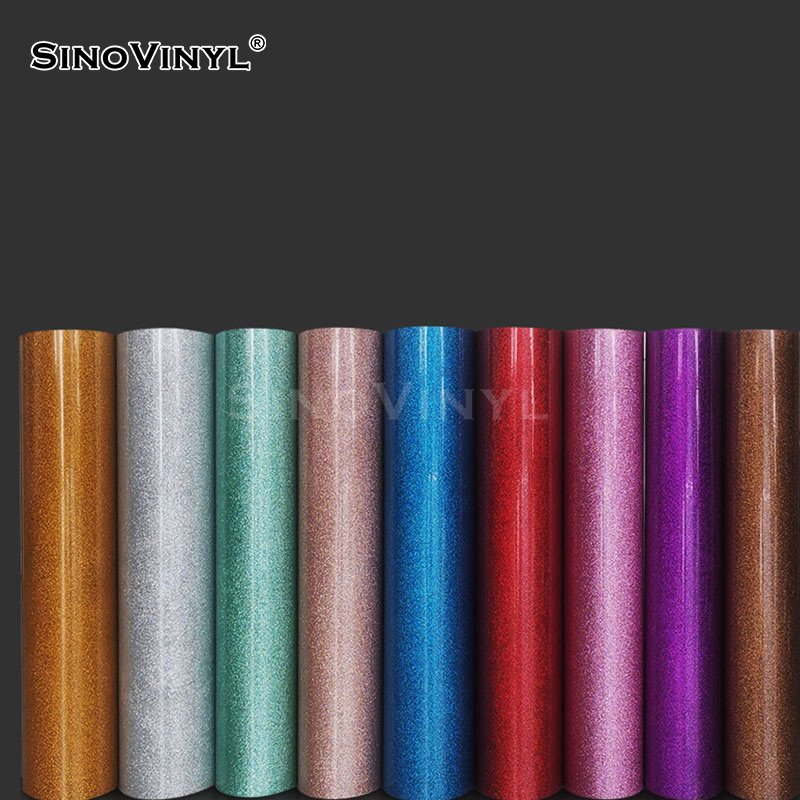

6. Using a Low-Quality Vinyl

Inferior quality vinyl may not have strong adhesive properties or might not withstand washing and wear. Invest in a reputable brand of HTV to ensure the best results and longevity.

7. Applying HTV on Heat-Sensitive Materials

Some materials, like thin plastics or heat-sensitive fabrics, can get damaged or melt under the heat press. Always check the compatibility of the material before attempting HTV application.

8. Uneven Pressure Distribution

If the pressure is not distributed evenly during pressing, it can cause parts of the vinyl to adhere better than others, leading to peeling or poor adhesion.

9. Ignoring Carrier Sheet Placement

Placing the carrier sheet over the HTV during the heat press can cause the vinyl to wrinkle or result in an uneven application. Always ensure the carrier sheet is removed before pressing.

10. Washing and Drying Errors

Not following the proper washing and drying instructions for garments with HTV can lead to premature fading, peeling, or cracking of the vinyl design.

By being aware of these common mistakes and taking the necessary precautions, you can ensure a successful and long-lasting heat transfer vinyl application.

Final Words

In conclusion, mastering the art of heat transfer vinyl removal is a crucial skill for any crafting enthusiast. By understanding the potential pitfalls and avoiding common mistakes during the application process, you can ensure your designs stand the test of time. Whether it’s selecting the right fabric, adhering to proper temperature and time settings, or using the appropriate tools, following this ultimate heat transfer vinyl removal tutorial will empower you to say goodbye to vinyl mistakes.