What happens if the temperature is too low or too high during application?

The temperature plays a crucial role in the successful application of heat transfer vinyl (HTV) onto fabrics. Both temperatures that are too low and temperatures that are too high can have negative effects on the outcome of the application:

Temperature Too Low

– If the temperature is too low, the adhesive on the HTV may not activate and bond properly with the fabric. This can lead to incomplete or weak adhesion.

– The HTV might not stick securely to the fabric, and there’s a higher chance of it peeling off after a short period of use or after washing.

– The design might not transfer completely, resulting in areas where the HTV does not fully adhere to the fabric.

Temperature Too High

– Excessive heat can cause the adhesive on the HTV to melt or burn, which can lead to discoloration or scorch marks on both the HTV and the fabric.

– High temperatures can damage delicate fabrics or cause them to shrink, warp, or lose their original texture.

– The vinyl material itself might start to degrade, losing its original color or finish due to overheating.

– In some cases, extremely high temperatures can cause the HTV to bubble or blister, resulting in an uneven and unattractive appearance.

It’s important to follow the manufacturer’s guidelines for temperature and time settings provided with the specific type of heat transfer vinyl you’re using. Testing on a small piece of fabric or a scrap garment before applying HTV to your final project can help you determine the optimal temperature and time settings for a successful application without damaging the fabric or the vinyl.

Can HTV application be successful with a heat press, iron, or other heat sources? What are the differences in temperature and time requirements?

Yes, HTV application can be successful using various heat sources, including a heat press, household iron, and other heat tools. However, the temperature and time requirements can differ based on the heat source used. Here’s a breakdown of the differences:

1. Heat Press

A heat press is a specialized machine designed for applying heat and pressure to HTV and other heat transfer materials. Heat presses provide consistent heat distribution and pressure, which can result in more reliable and uniform application.

– Temperature

Heat presses typically have adjustable temperature controls, and the recommended temperature can vary based on the type of HTV and fabric. For example, common temperatures range from 300°F to 350°F (150°C to 175°C).

– Time

The recommended time for pressing HTV with a heat press is usually around 10 to 15 seconds. The exact time might vary depending on factors like the thickness of the vinyl and the fabric type.

2. Household Iron

While not as precise as a heat press, a household iron can still be used effectively for HTV application with careful attention to temperature and pressure.

– Temperature

Set your iron to the temperature recommended for the HTV you’re using. This is usually within the range of 300°F to 350°F (150°C to 175°C).

– Time

The time needed with an iron is generally longer than with a heat press due to the less even distribution of heat. You might need to press for 20 to 30 seconds or more, depending on the vinyl type and fabric.

3. Other Heat Sources

Other heat sources, such as heat guns or handheld mini-presses, can also be used for HTV application, but they require more caution and precision due to their localized heat application.

– Temperature

Temperature requirements might be similar to those of a household iron, but they can vary. It’s important to experiment and find the right temperature that works for your specific heat source.

– Time

The time required might be longer compared to a heat press due to the limited coverage area of the heat source. Experimentation and practice are key to achieving successful results.

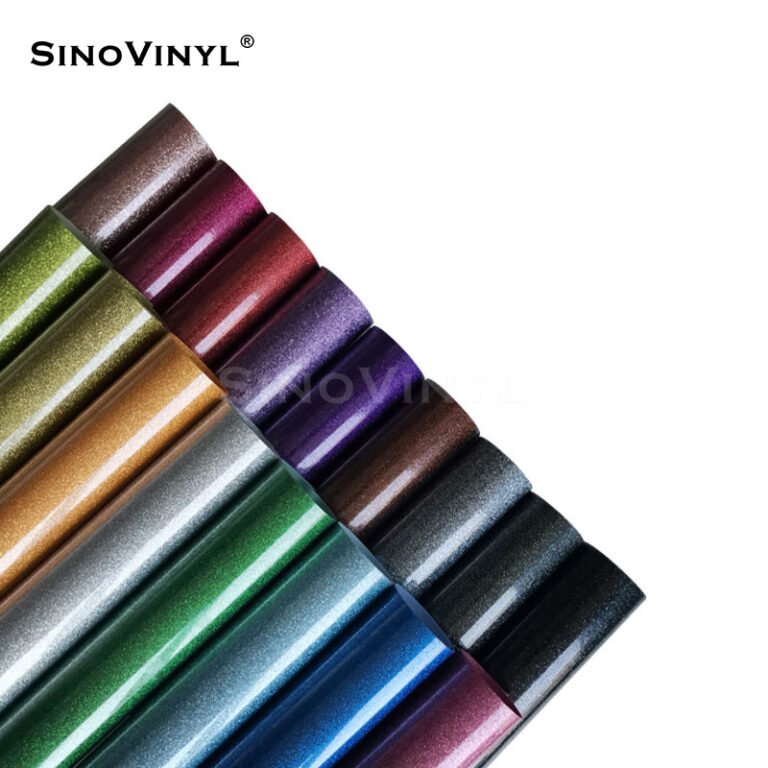

In all cases, it’s crucial to follow the manufacturer’s guidelines for the specific HTV you’re using. Different HTV types (such as standard, glitter, metallic, etc.) might have slightly different temperature and time recommendations. Additionally, consider using a Teflon or silicone sheet to protect the vinyl and fabric from direct contact with the heat source.

Remember that practice and experimentation will help you determine the optimal temperature and time settings for your chosen heat source and materials. Always test a small piece of HTV on a scrap fabric before applying it to your final project.