Are you new to the world of crafting and customizing clothing? If so, you might be wondering about the differences between vinyl and heat transfer vinyl (HTV). SINOVINYL is here to help you understand these materials and make informed choices for your projects.

Vinyl vs. Heat Transfer Vinyl: What’s the Difference?

Before we delve into the specifics, let’s clarify what vinyl and heat transfer vinyl are:

1. Vinyl (Adhesive Vinyl):

- Application: Adhesive vinyl is designed for a wide range of surfaces, including glass, wood, and plastic. It’s not intended for use on fabrics like T-shirts.

- Characteristics: Adhesive vinyl has a sticky backing that adheres to surfaces when pressure is applied. It’s commonly used for wall decals, stickers, and outdoor signage.

- Heat Sensitivity: It does not require heat for application; instead, pressure ensures adhesion.

2. Heat Transfer Vinyl (HTV):

- Application: HTV, also known as iron-on vinyl, is specifically designed for fabrics. It’s perfect for customizing clothing, textiles, and cotton materials.

- Characteristics: HTV comes with a heat-activated adhesive on one side and a carrier sheet on the other. When heat and pressure are applied, it adheres to fabric surfaces.

- Heat Sensitivity: Heat is crucial for transferring HTV onto fabric; it requires a specific temperature and time for a secure bond.

Why Choose SINOVINYL Heat Transfer Vinyl?

Now that you know the difference between vinyl and HTV, let’s focus on SINOVINYL’s Heat Transfer Vinyl and why it’s the ideal choice for your fabric customization projects:

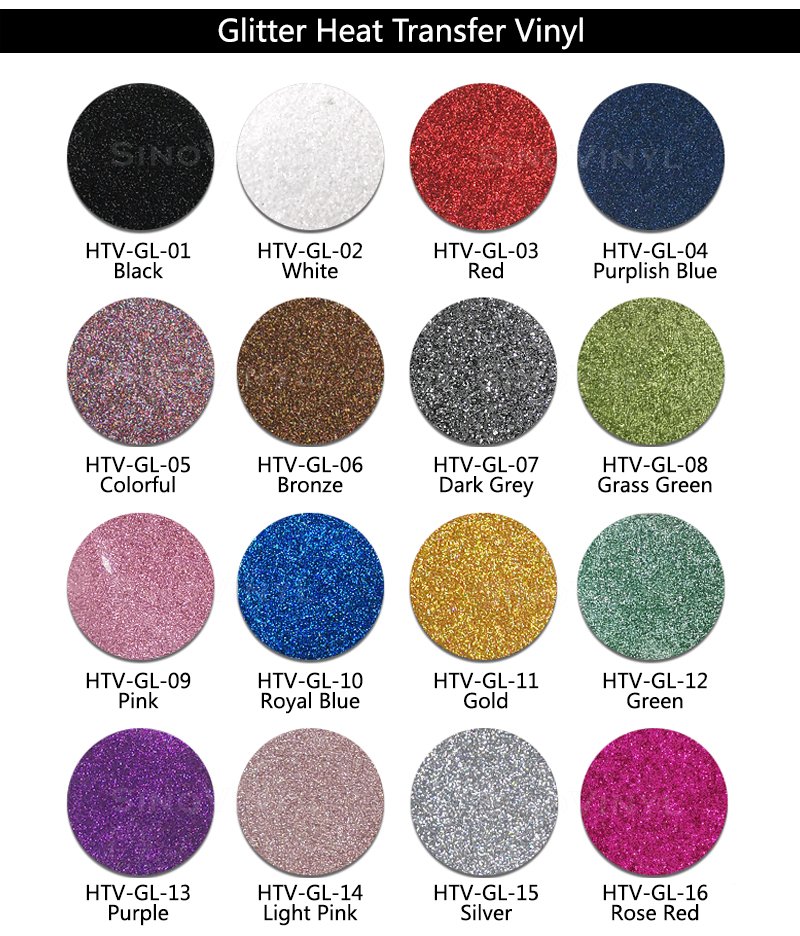

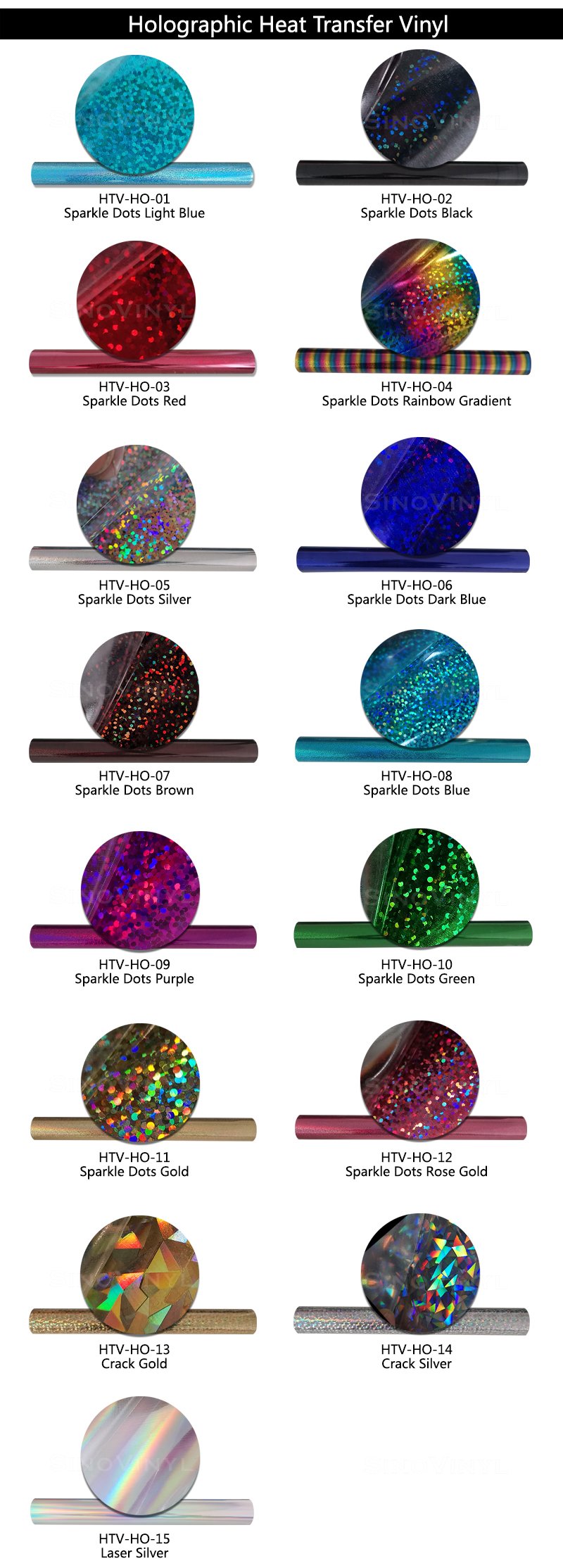

- Size and Style: SINOVINYL offers generous rolls of HTV, measuring 0.5×25 meters, providing you with ample material for numerous creations. It’s available in a wide range of PU colors to suit your creative preferences.

- Versatile Application: SINOVINYL HTV is engineered for use on T-shirts, clothing, textiles, cotton, and various fabric types. It’s perfect for personalizing your wardrobe and creating unique gifts.

- Transfer Pressure: The recommended transfer pressure for SINOVINYL HTV is 20-30 pounds, which is easy to achieve with a standard heat press or household iron. Beginners and experienced crafters alike can use it with confidence.

- Optimal Heat Settings: To achieve the best results, heat SINOVINYL HTV at temperatures ranging from 150-160°C (302-320°F) for 8-12 seconds. These settings ensure a secure bond without damaging the fabric.

- Peeling Method: After the heat transfer process, SINOVINYL HTV can be peeled cold. This means you don’t have to wait long to reveal your beautifully customized fabric.

Conclusion

In summary, the key difference between vinyl and heat transfer vinyl lies in their intended applications. Vinyl is best suited for hard surfaces like glass and wood, while heat transfer vinyl is designed exclusively for fabrics. When it comes to fabric customization projects like T-shirts, clothing, and textiles, SINOVINYL’s Heat Transfer Vinyl is your reliable partner. With its user-friendly features, variety of colors, and precise application parameters, you can turn ordinary fabrics into personalized masterpieces. Make your creations stand out with SINOVINYL HTV today!