Understanding Heat Transfer Vinyl: A Comprehensive Overview

Heat transfer vinyl (HTV) is a specialized material widely used in the world of crafting and personalization. It is a type of vinyl that can be cut into various shapes, designs, or letters using a cutting machine and then transferred onto fabrics or other surfaces using heat and pressure. The heat activates the adhesive on the vinyl, allowing it to adhere permanently to the desired item.

Here’s a comprehensive overview of heat transfer vinyl:

1. Composition

Heat transfer vinyl is typically made of polyurethane or PVC material. It comes in rolls or sheets with an adhesive backing protected by a release liner.

2. Types of HTV

There are various types of heat transfer vinyl available, each with unique characteristics. Standard HTV is great for basic designs, while specialty HTV like glitter, holographic, foil, and flock offer different textures and visual effects.

3. Cutting Process

To create designs, you need a cutting machine (e.g., Cricut, Silhouette) that works with design software. The machine cuts the vinyl according to your design, and you can then weed out the excess vinyl, leaving only the desired design on the carrier sheet.

4. Heat Press vs. Iron-on

HTV can be applied using a heat press machine or a household iron. A heat press provides consistent and even heat distribution, leading to better and long-lasting results.

5. Fabrics and Surfaces

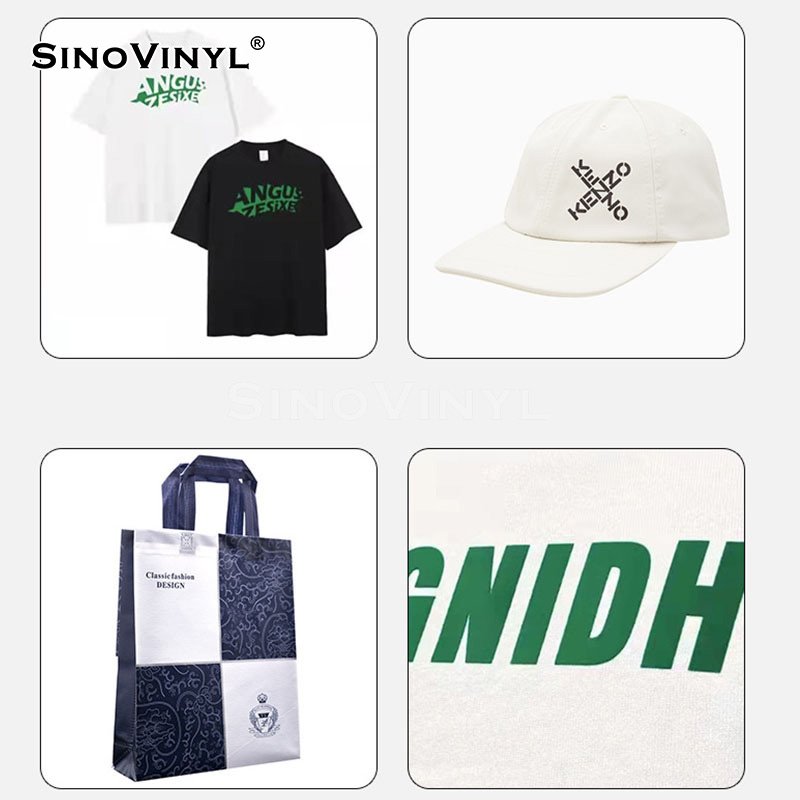

HTV works best on cotton, polyester, and cotton/poly blends. It can also be used on certain hard surfaces like mugs, glass, wood, and more, depending on the type of vinyl used.

6. Temperature and Time

The proper temperature and pressing time are crucial for successful transfers. Each vinyl type has specific heat application guidelines, which must be followed to avoid damage to the material.

7. Peeling and Aftercare

Once heat-applied, HTV can have either a warm or cold peel. Follow the recommended peeling method for the best results. Additionally, take care when washing and drying garments with applied HTV to prolong its lifespan.

8. Layering and Multi-Color Designs

HTV allows for layering, enabling you to create intricate, multi-colored designs. When layering, apply one layer at a time and use a heat-resistant cover sheet to protect previous layers.

9. Safety Precautions

When working with heat transfer vinyl, take necessary safety precautions. Ensure good ventilation in your workspace and avoid overheating the vinyl to prevent the release of harmful fumes.

10. Application Tips

Consider pre-pressing the fabric before applying HTV to remove wrinkles and moisture, which can affect the transfer. Also, test cuts and press on scraps to fine-tune your settings before working on the final project.

Understanding the fundamentals of heat transfer vinyl will help you create beautiful, personalized items, whether for yourself, as gifts, or as part of a small crafting business. Always refer to the manufacturer’s guidelines for specific products, and with practice, you’ll master the art of using HTV to transform your designs with ease and confidence.

Comparing Heat Transfer Vinyl and Screen Printing: Pros and Cons

When it comes to customizing fabrics and apparel, both heat transfer vinyl (HTV) and screen printing are popular methods. Each technique has its unique advantages and disadvantages, catering to different needs and preferences of crafters and businesses. Let’s explore the pros and cons of both heat transfer vinyl and screen printing:

Heat Transfer Vinyl (HTV)

Pros

1. Easy and Beginner-Friendly

HTV is relatively simple to use, making it ideal for beginners and DIY crafters.

2. Low Initial Cost

The equipment required for HTV is more affordable compared to screen printing setups.

3. Versatility

HTV comes in various colors, patterns, and textures, allowing for intricate designs and personalized creations.

4. Ideal for Small Batches

It is cost-effective for producing small quantities of custom items or one-off designs.

5. Quick Turnaround

HTV application typically requires less time, making it suitable for on-demand projects.

Cons

1. Layer Limitations

Layering multiple colors can be challenging and may add thickness to the design.

2. Durability

HTV may not be as durable as screen printing, especially with frequent washing and heavy wear.

3. Not Suitable for Large Productions

It becomes less cost-effective and time-consuming when producing large quantities.

Screen Printing

Pros

1. High Durability

Screen printing offers long-lasting and robust prints, suitable for high-wear garments.

2. Cost-Effective for Large Orders

As the quantity increases, the cost per unit decreases, making it ideal for bulk production.

3. Vibrant Colors

Screen printing allows for more vibrant and opaque colors, especially on dark fabrics.

4. Suitable for Complex Designs

Fine details and intricate designs can be reproduced accurately with screen printing.

5. Consistency

Screen printing provides uniformity across large batches, ensuring a consistent finish.

Cons

1. Initial Setup Cost

Screen printing requires more expensive equipment and a larger upfront investment.

2. Time-Consuming

The preparation process, including creating screens for each color, can be time-consuming.

3. Skill and Experience

Achieving high-quality screen prints demands expertise and experience.

4. Limited Customization

Customization options may be limited for individual orders compared to HTV.

Ultimately, the choice between heat transfer vinyl and screen printing depends on the specific requirements of your project, budget constraints, and desired outcome. HTV works well for small-scale projects and customization, while screen printing shines when producing large quantities of durable and consistent prints. Consider your needs and preferences to select the best method for your designs.

(Click the picture to learn more)

You May Interest

https://sinohtvvinyl.com/how-to-remove-heat-transfer-vinyl/