Meta Describition

A detailed look at the types of vinyl materials used for puff heat transfer, including their composition, thicknesses, and color options. Additionally, discuss the tools needed for successful puff vinyl application.

Puff It Up: Tools to Enhance the 3D Effect in Puff Vinyl Designs

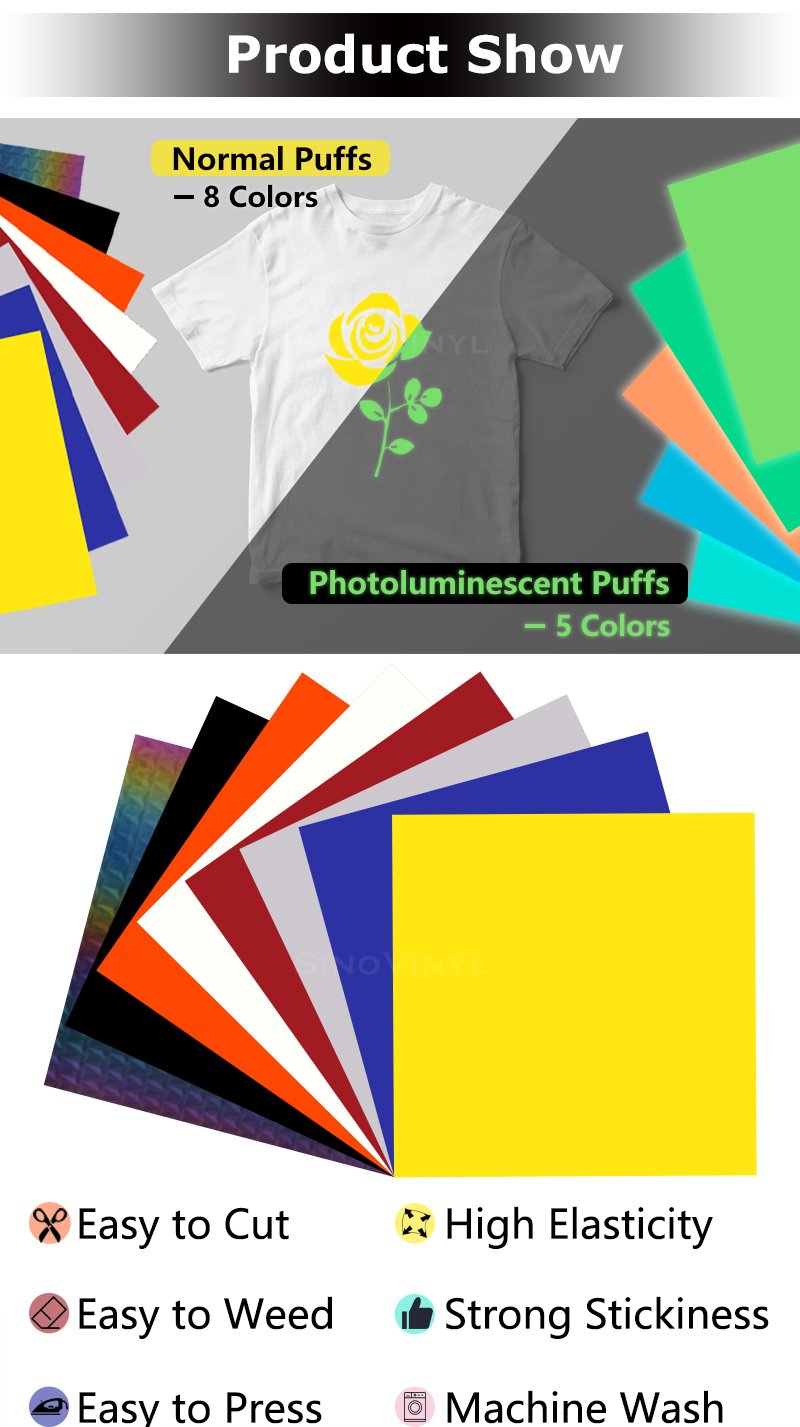

Types of Puff Vinyl Materials

Puff vinyl materials come in several varieties, each contributing to the distinct texture and effect of the final design. These include:

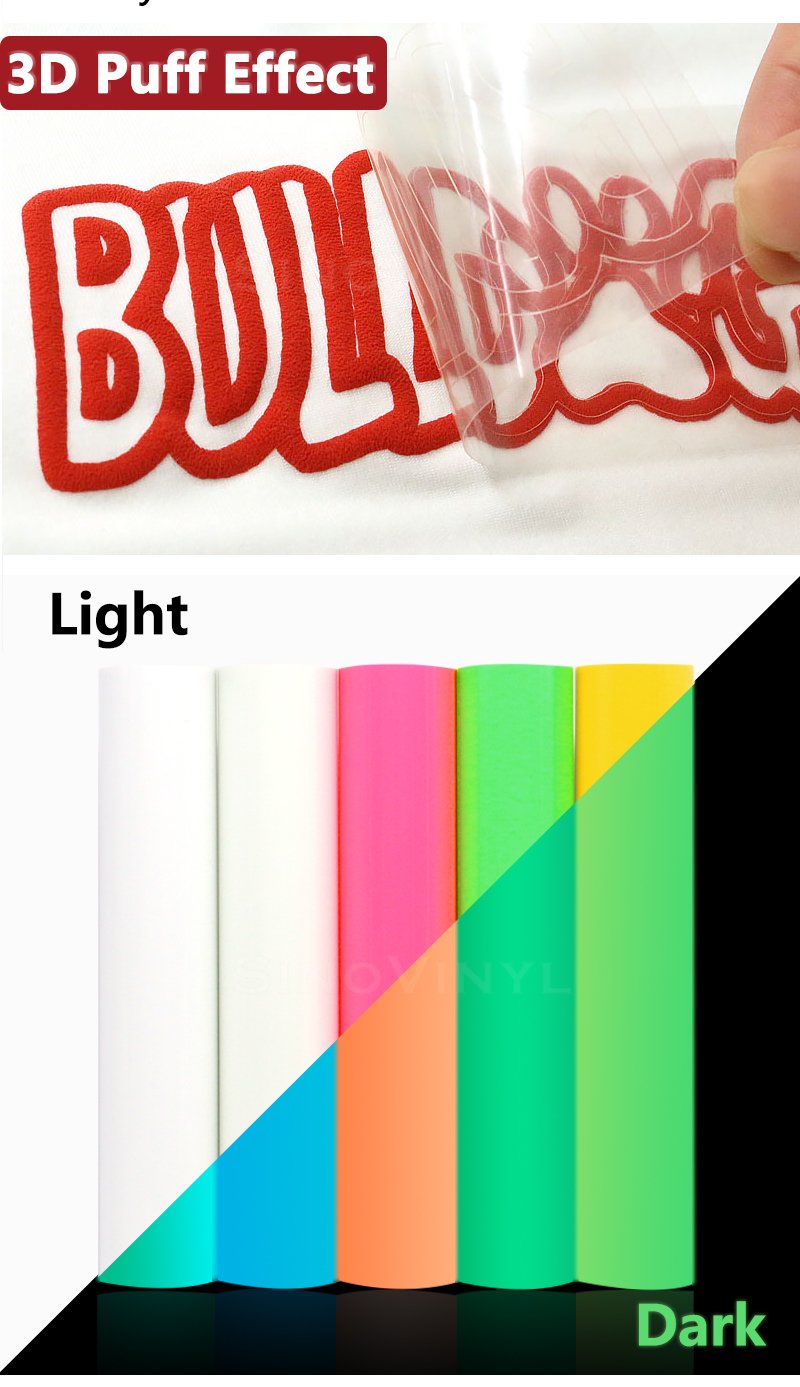

1. Standard Puff Vinyl

Composed of a vinyl layer with puff-inducing additives, this material puffs up when exposed to heat, creating a raised, three-dimensional effect.

2. Glitter Puff Vinyl

Infused with glitter particles, this type adds an extra layer of sparkle to your designs while retaining the puff effect.

3. Metallic Puff Vinyl

With a metallic finish, this material combines shine and dimension for designs that truly stand out.

4. Patterned Puff Vinyl

These come with pre-printed patterns or textures, further enhancing the visual appeal of the design after puffing.

Choosing the Right Thickness

Puff vinyl thickness can greatly influence the final outcome of your design. Thickness options typically range from 100 microns to 400 microns.

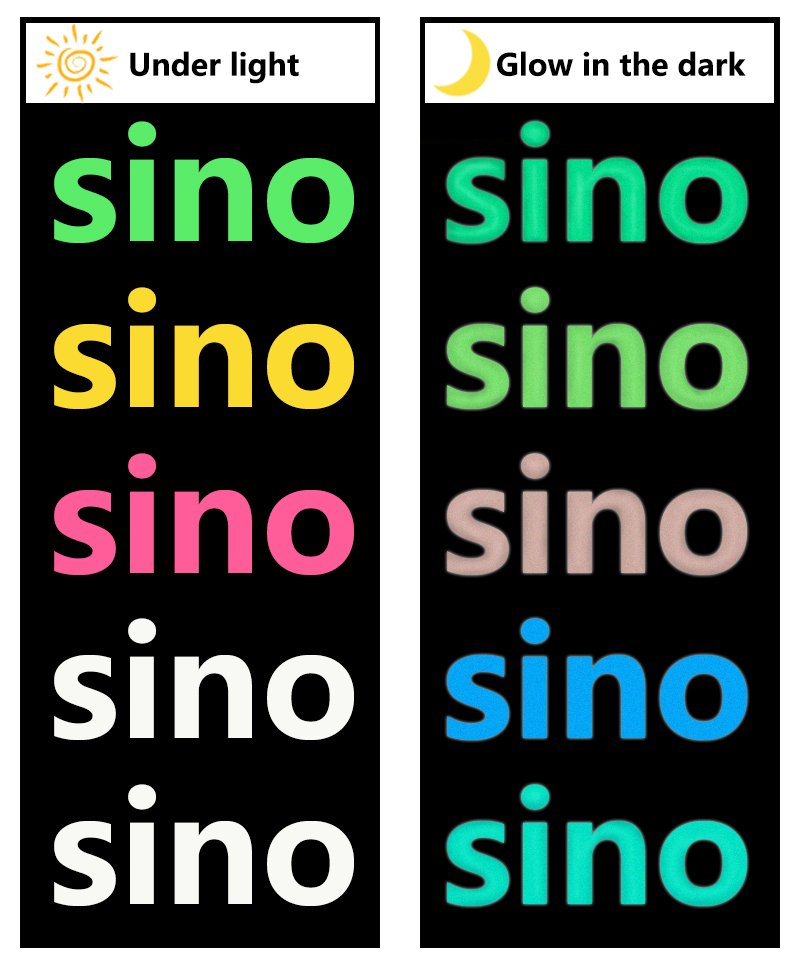

Exploring Color Options

Puff vinyl is available in a wide array of colors, making it versatile for various design concepts. From vibrant solids to metallic hues and even special effects like holographic finishes, the color spectrum is virtually limitless.

Essential Tools for Puff Vinyl Application

Achieving a successful puff vinyl transfer requires the right tools and techniques. Here are the key tools you’ll need:

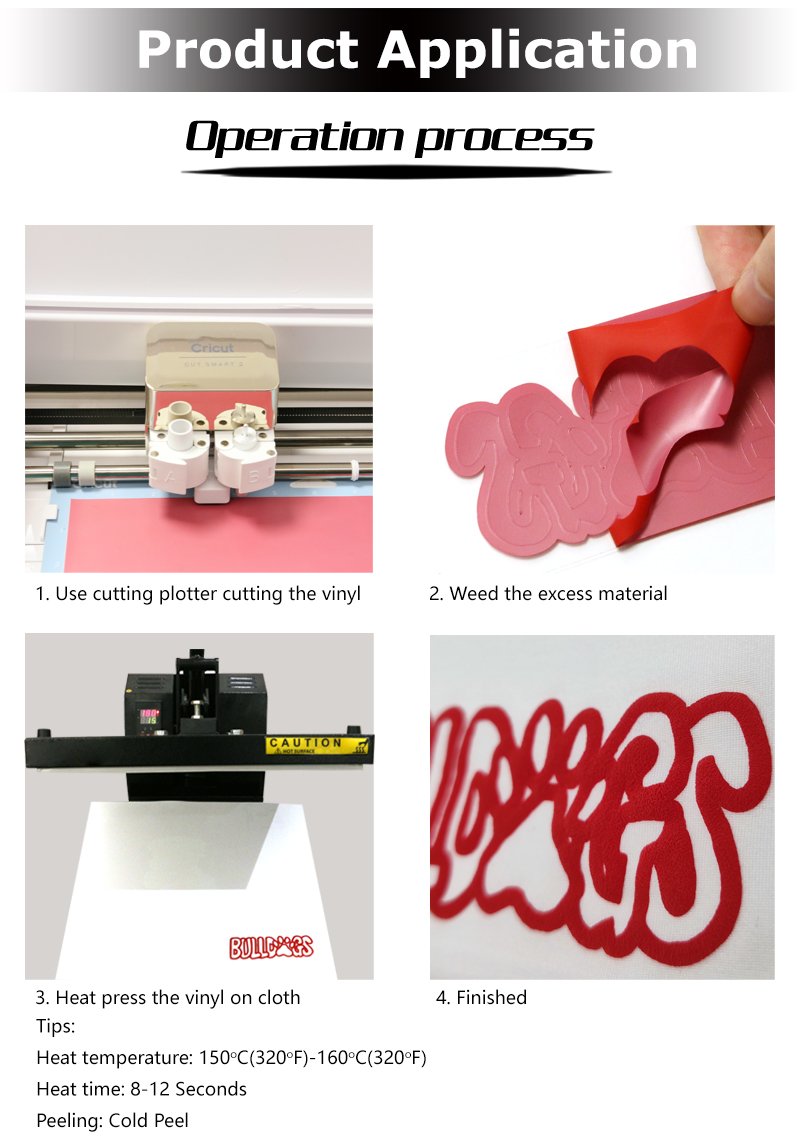

1. Cutting Machine

A precision cutting machine like a vinyl cutter is essential for accurately cutting out your designs from the puff vinyl sheet.

2. Weeding Tools

These tools, including hook tools and tweezers, help remove excess vinyl from around your design after cutting.

3. Heat Press

A heat press is crucial for applying heat and pressure to activate the puffing effect. Ensure your heat press has adjustable temperature and pressure settings.

4. Heat Transfer Cover Sheet

Protects the vinyl and fabric from direct contact with the heat press, preventing scorching or damage.

5. Teflon Sheet or Parchment Paper

Placed over the puff vinyl design before heat pressing, it prevents the vinyl from sticking to the upper heat platen.

6. Heat-Resistant Tape

Holds the design in place on the fabric during the heat pressing process, ensuring precise alignment.

7. Lint Roller

Ensures the fabric surface is clean and free of debris before application, resulting in better adhesion.

8. Ruler or T-Square

Helps align and position your design accurately on the fabric before pressing.