Applying 3D Puff Vinyl on Different Fabrics

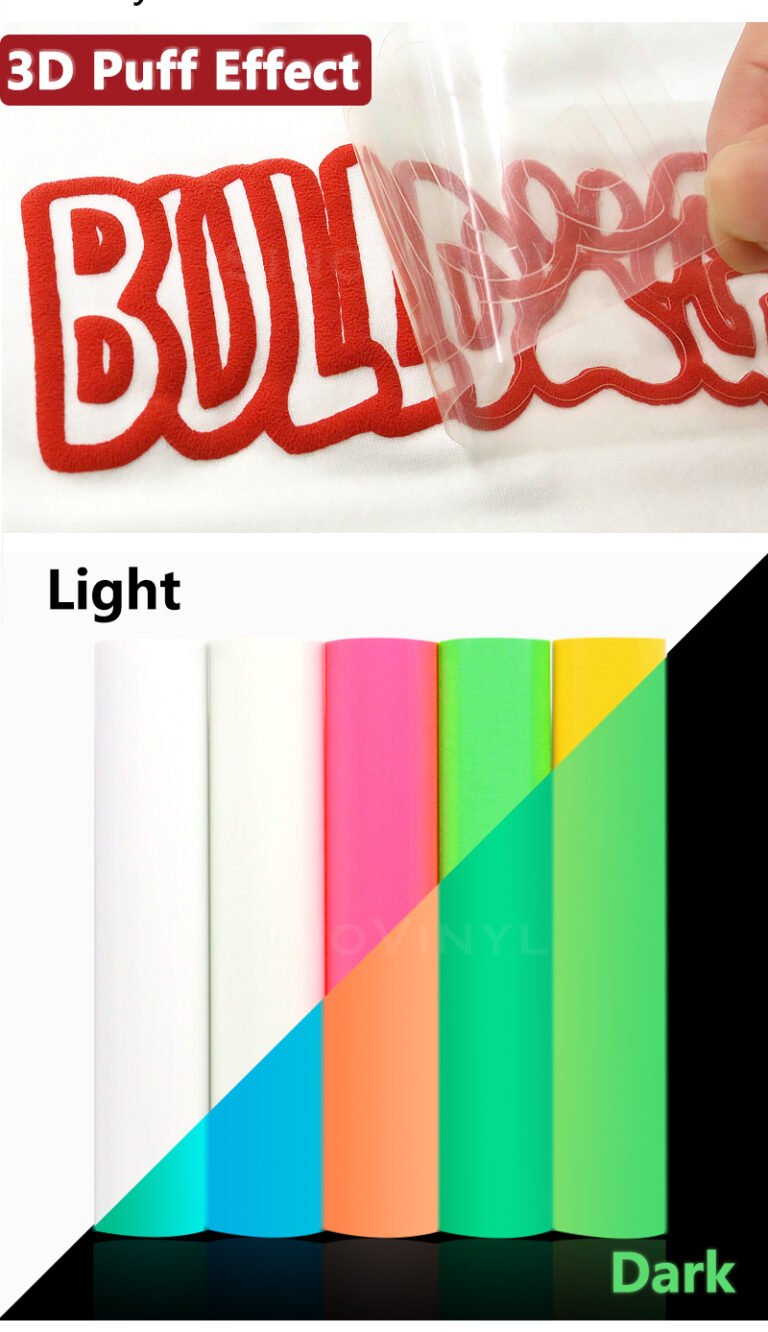

The process of applying 3D puff vinyl on various fabrics entails utilizing the distinctive heat transfer technique of this vinyl to produce elevated and textured designs on different fabric types.3D puff vinyl is a specialized heat transfer material that puffs up when subjected to heat, resulting in a three-dimensional, raised effect on the surface of the fabric.

The process of applying 3D puff vinyl to different fabrics typically involves the following steps:

1. Design Creation

The first step is to create or select a design suitable for 3D puff vinyl application. Designs with bold, solid shapes and distinct lines tend to work best with this technique.

2. Cutting the Vinyl

The design is then cut into the 3D puff vinyl material using a vinyl cutter or plotter. The vinyl is usually thicker than regular heat transfer vinyl to achieve the puff effect.

3. Weeding

After cutting, the excess material around the design is removed carefully in a process called weeding, leaving only the intended design on the vinyl carrier.

4. Prepping the Fabric

The fabric to be decorated is prepared by ensuring it is clean, dry, and free from any wrinkles. It is crucial to have a smooth and flat surface to ensure proper adhesion of the 3D puff vinyl.

5. Heat Press Application

The cut and weeded 3D puff vinyl is then positioned on the fabric with the carrier side facing up. The heat press machine is preheated to the recommended temperature for the specific fabric type.

6. Pressing the Vinyl

The heat press machine is closed, and heat and pressure are applied to the fabric and 3D puff vinyl for a specified amount of time. The heat causes the vinyl to expand and puff up, adhering to the fabric surface.

7. Peeling and Cooling

Once the pressing time is complete, the heat press is opened, and the carrier sheet is carefully peeled away from the fabric. The puff vinyl should now be permanently adhered to the fabric, creating the raised, three-dimensional effect.

Different Fabrics Types

It’s essential to consider the fabric type when applying 3D puff vinyl, as different fabrics have distinct characteristics that can affect the heat transfer process:

– Cotton

Cotton fabrics are generally well-suited for 3D puff vinyl applications.

– Polyester

Polyester fabrics can also work with 3D puff vinyl, but caution should be exercised as they are more sensitive to heat.

– Blends

Fabric blends containing both cotton and polyester can be used, but the heat transfer process should be adjusted to accommodate the characteristics of both fibers.

– Nylon and Spandex

These fabrics are challenging for 3D puff vinyl applications due to their sensitivity to high heat. Specialized low-temperature puff vinyl and careful heat press settings may be required for successful application.

You May Interest

https://sinohtvvinyl.com/puffs-heat-transfer-vinyl/

https://sinohtvvinyl.com/photoluminescent-puffs-heat-transfer-vinyl/